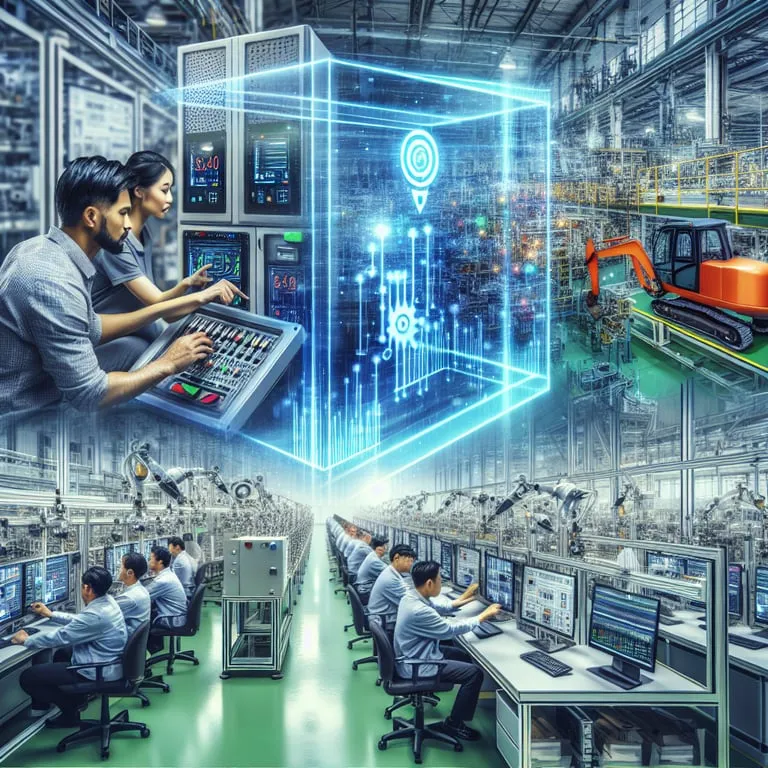

How Korea’s Smart Factory Sensors Are Entering US Manufacturing

You’ve probably noticed it already—those compact, ridiculously capable sensors from Korea quietly showing up on US plant floors, slotting into legacy lines like they were born there요.

It didn’t happen overnight, and it didn’t happen by accident다.

In 2025, what’s really moving the needle is a blend of rugged hardware, smart edge AI, and down-to-earth integration that OT and IT teams can both live with요.

Let’s walk the floor together and unpack how this wave is getting through the dock door—and why it’s sticking다.

Why US manufacturers are looking at Korea now

Vision-first roots turned factory muscle

Korean vendors spent a decade getting scary good at imaging, optics, and AI inference다.

If you followed machine vision, you saw the signal: a Korean deep-learning vision startup, Sualab, was acquired by Cognex, validating the country’s software and model-optimization chops요.

That DNA—fast inference, low-light performance, clever model compression—migrated into industrial sensors that now handle OCR at 120–240 fps, sub-20 ms classification latency, and one-click model updates at the edge다.

You feel it when a single smart camera replaces a brittle rules-based setup that needed three lighting tricks and weekly tweaks요.

Rugged plus refined hardware

This isn’t delicate lab gear다.

You’re seeing IP67/69K housings, M12 connectors, 24 VDC power, -20 to 60°C operating ranges, and 3–5 g vibration tolerance across the catalog요.

Vibration sensors sample up to 16 kHz with 24-bit ADCs and on-sensor envelope analysis다.

Energy meters log harmonics to the 63rd, capture sags/swells in 1–2 cycle windows, and sync time via PTP for traceable events요.

The cost-to-value sweet spot

For many US teams, the math is what lands the PO다.

Wireless vibration nodes at $180–350 each, gateways in the $400–800 range, and vision sensors commonly at $1,200–3,000 hit a payback window of 6–12 months when they cut unplanned downtime by 10–20%요.

Subscription pricing (think $3–10 per asset per month for analytics) lets ops scale without scary capex spikes다.

It’s the familiar story: small pilot, fast ROI, and then scale with confidence요.

5G and lightweight OT networks that just work

Korean vendors leaned into practical wireless—BLE Mesh for dense sensors, sub-GHz for long-reach, and CBRS-ready 4G/5G for mobile assets다.

On the floor, you’ll see private 5G handling AGVs and high-throughput vision, while MQTT Sparkplug B streams time-series data to SiteWise or Ignition with minimal ceremony요.

No mystery—just stable links and predictable latency다.

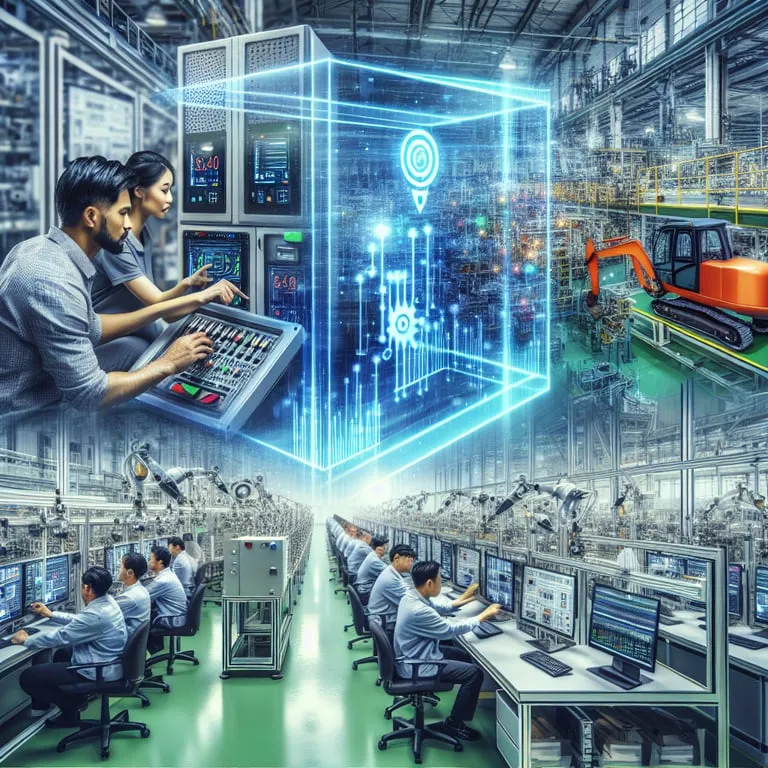

What’s actually entering the plant

Condition monitoring kits you can deploy before lunch

- Triaxial vibration + temperature nodes with 2–5 year battery life (depending on 1–15 minute sample intervals)다.

- On-sensor features: crest factor, kurtosis, envelope RMS, order tracking for VFD-driven assets요.

- Gateways perform edge inference (isolation forest or autoencoder models) and publish anomalies in OPC UA and Sparkplug topics다.

A Midwest stamping plant saw unplanned press stoppages drop 27% in 90 days using nothing more than drive-end sensors and a simple model trained on “good” baseline data요.

Start simple, prove value, and let the wins stack up다.

Smart vision sensors that train on the line

- 5–12 MP global shutter sensors, liquid lens options, and white/IR strobes integrated요.

- On-device training in 20–40 images for binary OK/NOK, and 100–300 for fine-grained defect classification다.

- OCR with character confidence scoring and per-region lighting profiles요.

Teams like automotive Tier-1s love these when model updates during changeovers take five minutes, not a lab session다.

Faster changeovers and fewer false rejects keep OEE climbing요.

Energy and power quality insights beyond a green dashboard

- Class 0.5S metering accuracy, harmonics up to the 63rd, waveform capture at 256–512 samples per cycle다.

- Tagging against production orders shows kWh per good unit and kWh per scrap—gold for continuous improvement요.

- Typical outcomes: 8–12% energy intensity reduction within a quarter, often from compressed air leaks and idle baseload discovery다.

Power quality fixes also reduce nuisance trips and protect sensitive electronics요.

Safety and presence sensing done quietly

- PL d / SIL 2 safety-rated light curtains and area scanners that speak CIP Safety or PROFIsafe다.

- mmWave radar presence detection that’s dust-tolerant where optical sensors choke요.

- Guided restart and muting logic prebuilt to keep audits calm and maintenance happy다.

It’s safety that earns trust without slowing the line요.

How they’re getting through the US door

Certifications and standards that matter

US buyers are right to be picky다.

- UL 61010-1 and cUL listings, NEMA Type 4X/IP67 ratings요.

- FCC Part 15 Subpart B/C/E, IC certification, and CB scheme reports다.

- Cyber baselines aligned to NIST SP 800-82, IEC 62443-4-2, and secure boot with signed OTA firmware요.

Defense-facing suppliers pursue CMMC 2.0 alignment and FIPS 140-3 validated crypto when required다.

For public-sector plants, TAA-compliant origin from Korea checks the procurement box요.

Interop without drama

No one wants a protocol hostage situation다.

- OPC UA servers and companion specs for condition monitoring요.

- MQTT Sparkplug B payloads for Ignition, HiveMQ, and AWS IoT SiteWise다.

- EtherNet/IP and PROFINET variants where PLC integration is king요.

- Modbus TCP/RTU fallbacks because… plants are plants다.

Clean information models and open protocols shorten commissioning요.

Distribution and partnerships that lower risk

You’ll see parts on Mouser and Digi-Key for engineering pilots, then larger volumes via industrial distributors and system integrators다.

Vendors join ODVA and PI, publish EDS/GSDML files, and enter Rockwell and Siemens partner ecosystems to shorten the “Can we talk to this?” cycle요.

This is exactly how skepticism turns into a line item다.

Pilot to scale without the hangover

A simple pattern is winning요.

- Week 0–2: Define 3–5 KPIs tied to money (MTBF, FPY, kWh/unit)다.

- Week 2–6: Instrument 1–2 assets or a single cell, validate data quality, tune alarms요.

- Week 6–10: Prove value, lock standards (names, topics, tags), plan a 10x scale-up다.

- Day 90: Roll to a value stream with standard kits and playbooks요.

No endless pilots—every step creates artifacts your techs can reuse다.

Real-world outcomes US teams care about

Downtime shaved, ROI measured

- Rotating equipment: 10–20% fewer unplanned outages in 60–120 days요.

- OEE lifts of 3–8 points when quality and availability nudge together다.

- Payback in 6–12 months on vibration and energy kits is common when maintenance and production are aligned요.

Measure what matters and report in the language your CFO hears다.

Quality lifted with explainable AI

Edge models flag defects and show per-feature heatmaps or saliency overlays다.

That means your QE lead can see why a seal or weld was rejected in seconds, not argue over gut feel요.

Scrap drops of 5–15% are typical when rules-based checks were missing subtle variation다.

Explainability builds trust, and trust scales adoption요.

Energy trimmed and incentives captured

With metering tied to orders and assets, teams uncover idle baseload, compressed air losses, and poor PF penalties다.

Add utility rebates for instrumentation and VFD tuning, and your controller smiles요.

In many plants, power quality fixes reduce nuisance trips and protect sensitive electronics다.

Lower energy intensity becomes a repeatable project, not a one-off win요.

Cyber and IT alignment that sticks

- Device identity via X.509 with per-device keys다.

- TLS 1.3 to brokers, role-based access, and signed OTA with SBOMs published요.

- Network segmentation by cell/zone, with DPI for industrial protocols다.

IT can say yes faster when these are defaults, not custom asks요.

Practical buyer checklist for 2025

Performance numbers to verify

- Vibration bandwidth and noise floor (e.g., 0.01 g RMS resolution to 8–16 kHz)다.

- Vision latency under load, FPS at full resolution, and accuracy at low contrast요.

- Meter accuracy class and waveform capture depth for PQ analysis다.

- Wireless latency and packet success rate in your RF mess, not the lab요.

Security must-haves

- Secure boot, signed firmware, and recovery images다.

- Unique per-device credentials, certificate rotation, and revocation paths요.

- Role-based management with audit logs shipped to your SIEM다.

- Vendor SBOMs and vulnerability disclosure SLAs (30–90 days remediation)요.

TCO and commercial sanity

- Hardware list: sensors, gateways, mounting, and spares다.

- Software: per-asset or per-site pricing, overage on data egress, and analytics tiers요.

- Services: install, commissioning, model training, and playbooks included or optional다.

- Don’t forget changeover time and workforce training as part of ROI요.

Change management that respects the floor

- 30-minute toolbox talks for techs, with laminated quick-starts다.

- Alarms aligned to the language of the shift (amps, mm, mils)—not data science yo-yo terms요.

- A “no blame” pilot zone where teams can tune thresholds without fear다.

This is where adoption really lives or dies—make it friendly and repeatable요.

What to watch next

Tiny edge models that act in milliseconds

Model distillation and quantization are getting wild다.

Expect 1–2 MB models catching anomalies at 2–5 ms inference times on ARM Cortex-M7 class MCUs, making battery nodes smarter without killing life요.

Private 5G that’s production-ready

CBRS band private 5G is moving from slides to shifts요.

With uplink-heavy slices for vision and deterministic QoS for AGVs, you can run fewer wires without gambling on jitter다.

Interop standards gaining momentum

Sparkplug B and OPC UA Companion Specs for condition monitoring keep winning요.

The more vendors publish clean information models, the less custom glue you write다.

That’s time back to the team, not to consultants요.

Ready to try a small, value-tied pilot?

If you’ve been waiting for a sign to test Korean smart factory sensors, this is probably it요.

Start with one cell, measure ruthlessly, and scale what works다.

The tech is ready, the standards are friendly, and the business case talks in the language your CFO actually hears요.

When you’re ready, I’ll bring coffee and a torque wrench—we’ll make it hum together다.

답글 남기기